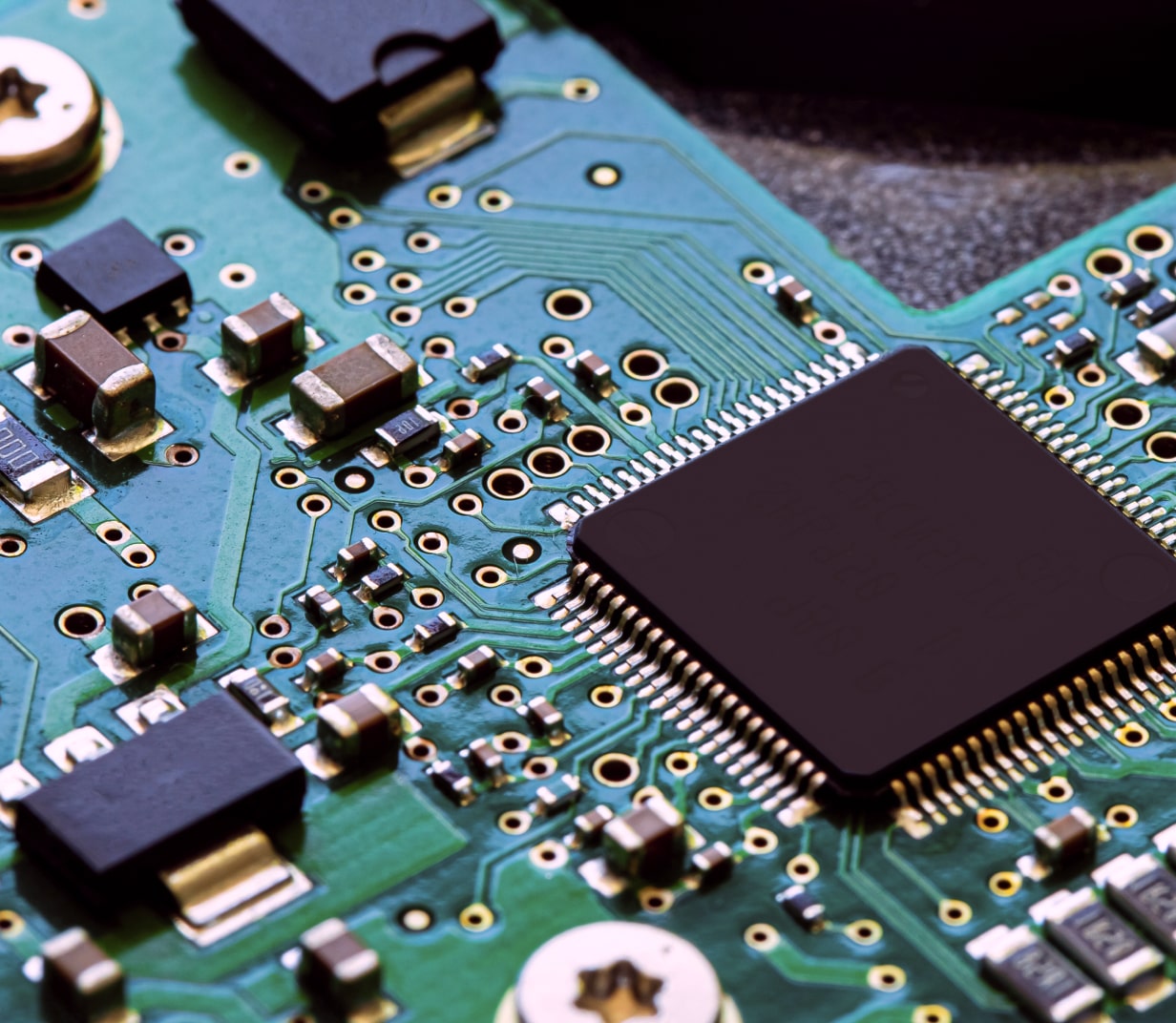

Advance electronic cooling and thermal analysis

Accurately predict and optimize the thermal performance of electronic systems

Speed up development and reduce costs

-

01

Setup models

Import electronic assemblies and components directly from CAD software or create geometries within the software itself. Easily define the thermal properties of materials, such as thermal conductivity, specific heat capacity and density.

-

02

Generate mesh

Automatically generate a mesh over a model, which is crucial for solving heat transfer equations and can be refined in areas of interest for increased accuracy.

-

03

Run simulations

Identify thermal sources, cooling mechanisms and boundary conditions and then run a simulation to solve heat transfer equations using the CFD solver. The software calculates temperature distributions and airflow patterns within and around the electronic assembly.

-

04

Analyze and optimize

Get detailed visualizations of temperature gradients, airflow velocities and other thermal characteristics along with thermal metrics such as junction temperatures to aid design iterations.

Enhance electronics

Predict temperature and airflow with precision

Reduce time and effort required to prepare simulations

Identify optimal thermal solutions

Reduce the need for physical prototyping

Enhance reliability

Collaborate effectively

Flotherm is an electronic cooling simulation software leader

Client success is our success

Applied CAx has been instrumental in providing advice and guidance when making critical decisions and implementing the correct solution to support our business processes. In an emerging industry such as Fusion, we face unique challenges every day. Applied has helped us pave the way in the digital transformation journey for this industry.

I highly recommend Applied CAx as a trusted partner for any organization seeking innovative software solutions. Their expertise, commitment to excellence and ability to meet the unique requirements of the aerospace industry have been instrumental in our success at Rocket Lab.

CFD has been the backbone of PacMar Technologies’ engineering advantage in the marine industry, and it’s really helped us accelerate our design process to get to working prototypes. PacMar is pushing the limits of the CFD code, and Applied CAx support helps facilitate it.

I greatly appreciate Applied CAx’s focus on providing practical solutions to real-world engineering problems, customer support and world-class training courses. They are a true partner in helping us expand our digital capabilities.

Most larger firms struggle to understand our unique desires. Not Applied CAx. It’s as if they intuitively grasp why we’re not like the competition—and why that matters. This collaboration, along with a bent for action, is the underpinning of our Engineering Digital Transformation.

AppliedCAx has been fantastic in helping us scale our growing business with the necessary software tools appropriately and cost effectively. Additionally, and on multiple occasions, Applied has been invaluable to us by providing immediate, quick turn-around licensing requests that proved vital in being able to serve our customers.

Our company faces immense challenges in adopting innovative digital engineering capabilities, and the thought leadership and executive engagement from Applied CAx have made all of the difference and accelerated our adoption of these cutting-edge tools and processes. The future success of X-Energy with respect to Design, Analysis, Build and Operations has been positively impacted and strengthened by our partnership with Applied CAx and their team.