Simulate design with Simcenter FLOEFD

Democratize the use of CFD analysis in the design process

Simplify the CFD analysis process with

Simcenter FLOEFD

-

01

Integrate with CAD

Simcenter FLOEFD embeds into leading CAD platforms. Perform simulations directly on CAD models, leveraging the native design environment and without the need for data translation or separate CFD software.

-

02

Setup models

Utilize smart meshing that automatically generates a mesh around CAD geometry. Define physical conditions such as material properties, heat sources, fluid properties and environmental conditions directly within the software interface.

-

03

Simulate phenomena

The FLOEFD solver computes the fluid flow, heat transfer and associated phenomena based on the defined conditions. Run parametric studies directly from the CAD model.

-

04

Visualize and analyze

Simcenter FLOEFD provides detailed visualization tools that allow users to view results in various formats such as contour plots, vector plots and iso-surfaces. Generate comprehensive reports that document the simulation inputs, results and conclusions.

-

05

Optimize and iterate

With the data obtained from simulations, engineers can iterate designs quickly. The close integration with CAD means that changes to the model geometry can be made easily, and simulations can be rerun immediately to see the effects of changes—facilitating rapid design optimization.

Accelerate your time to market

Make CFD accessible

Simcenter FLOEFD stands out for its robust set of features that integrate directly into CAD software, making advanced computational fluid dynamics (CFD) accessible to designers and engineers.

Increase accuracy with advanced meshing

An automatic meshing function adjusts the mesh granularity based on the flow and thermal conditions predicted in the model. This adaptive meshing saves time and enhances the accuracy of simulations.

Setup parametric variations with ease

Enable users to easily setup and compute multiple design scenarios by varying parameters directly within the CAD model, facilitating design optimization and decision-making.

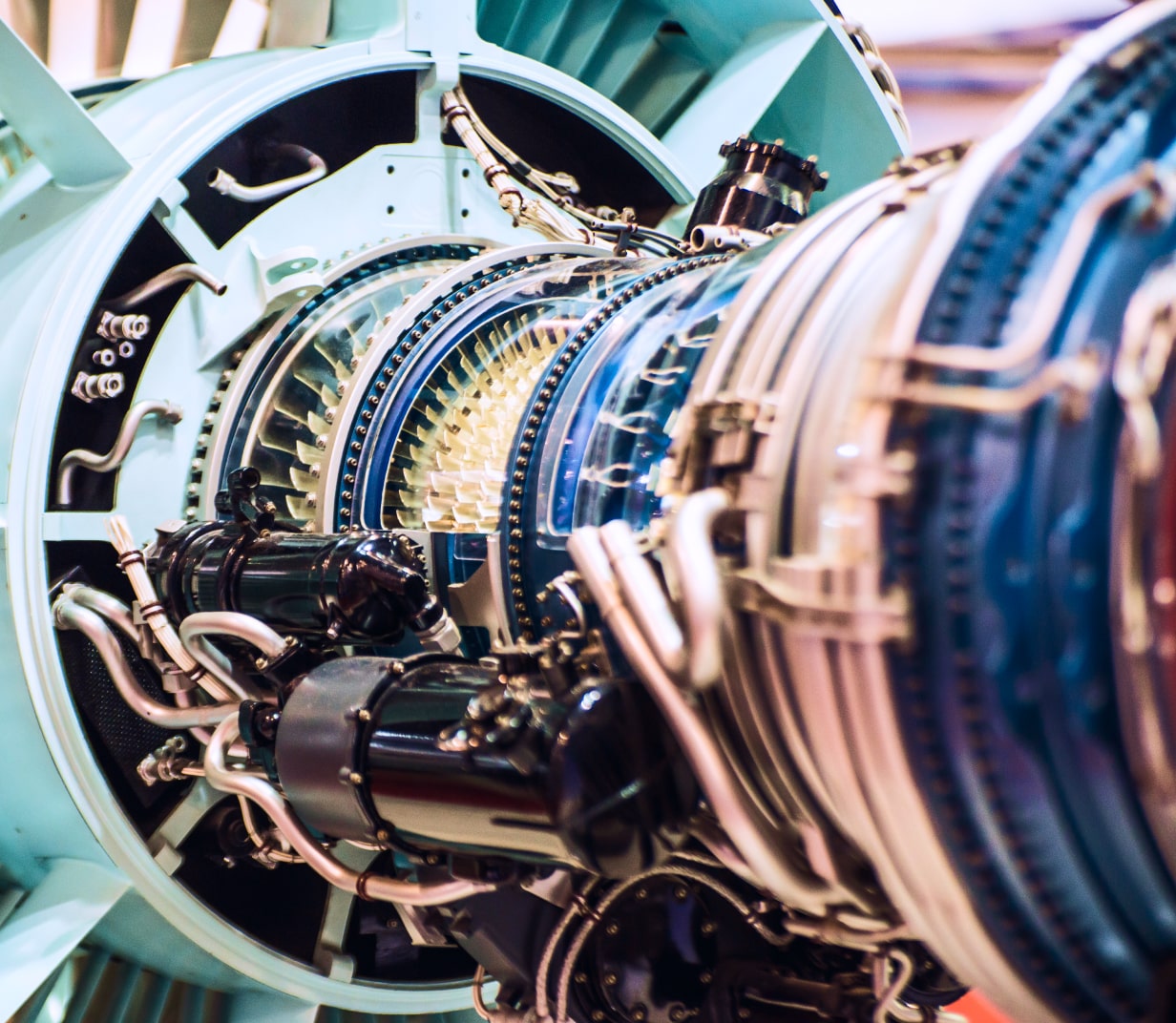

Solve complex challenges

The built-in solver efficiently handles complex simulations involving incompressible and compressible flows, heat transfer, radiation and rotating machinery—among others.

Access comprehensive insights

Simcenter FLOEFD simulates a wide array of physical processes, including conjugate heat transfer, porous media, real gasses and humidity, providing comprehensive insights into product behaviors under various conditions.

Increase workflow collaboration

Enhance team collaboration by allowing easy sharing of models and results, improving communication and efficiency across different stages of product development.

Shorten time to market with Simcenter FLOEFD

Client success is our success

CFD has been the backbone of PacMar Technologies’ engineering advantage in the marine industry, and it’s really helped us accelerate our design process to get to working prototypes. PacMar is pushing the limits of the CFD code, and Applied CAx support helps facilitate it.

I highly recommend Applied CAx as a trusted partner for any organization seeking innovative software solutions. Their expertise, commitment to excellence and ability to meet the unique requirements of the aerospace industry have been instrumental in our success at Rocket Lab.

Most larger firms struggle to understand our unique desires. Not Applied CAx. It’s as if they intuitively grasp why we’re not like the competition—and why that matters. This collaboration, along with a bent for action, is the underpinning of our Engineering Digital Transformation.

AppliedCAx has been fantastic in helping us scale our growing business with the necessary software tools appropriately and cost effectively. Additionally, and on multiple occasions, Applied has been invaluable to us by providing immediate, quick turn-around licensing requests that proved vital in being able to serve our customers.

Applied CAX has been the definition of a strategic partner to X-Energy.

They have demonstrated their expertise in both the technology as well as the unique challenges in the Nuclear Industry daily. Our company faces immense challenges in adopting innovative digital engineering capabilities, and the thought leadership and executive engagement from Applied CAx has made all of the difference and accelerated our adoption of these cutting-edge tools and processes.

The future success of X-Energy with respect to Design, Analysis, Build, and Operations has been positively impacted and strengthened by our partnership with Applied CAx and their team.