When you change software, you need to get your team on board as well. Getting staff trained and up to speed as quickly as possible is key to minimizing downtime. To facilitate the transition to the new software, Machinists Inc. relied on the engineering staff of Applied CAx, a Siemens software reseller that also operates a working machine shop and FEA consultancy. Starting with several sessions of onsite training, Applied engineers followed up with mentorship that dropped in weekly to help answer questions and troubleshoot challenges that came up.

In the first portion of this case study, we sat down with Charles Stangeland, CNC Programming Manager at Machinist Inc. to discuss the roadblocks they experienced with their previous CAM software, how it prompted their search for a better CAM solution, and how they evaluated their options before selecting Siemens NX.

However, choosing the software and buying it is just the first step.

Post Processor development

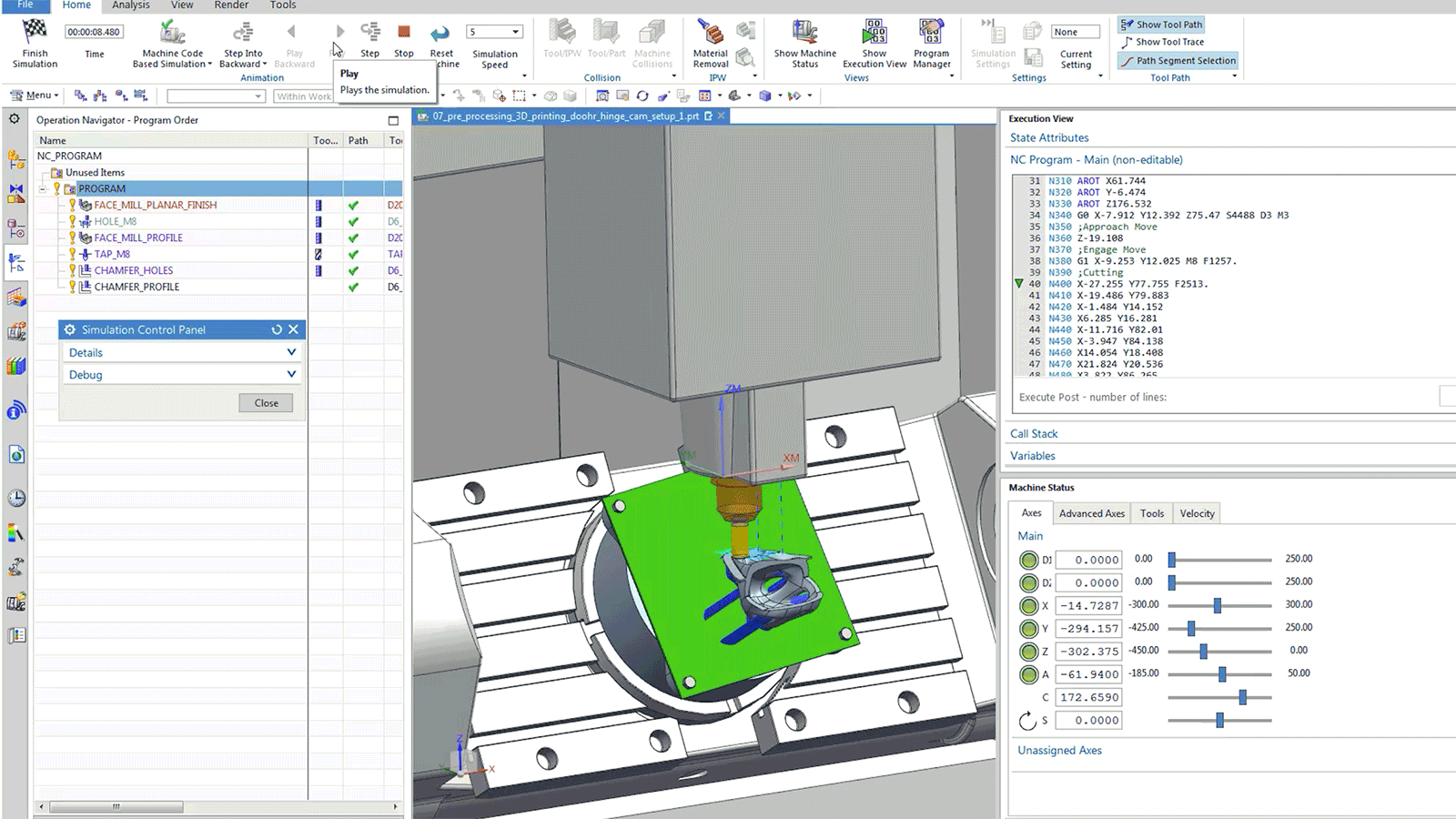

Once Machinists Inc had committed to the NX platform and purchased software, they needed Post Processors and a simulation kit. With the advanced kinematics of modern machine tools, MI needed to validate what they were doing to avoid running blind – even a minor programming error can result in a costly expense and set projects back days. Accurate machine simulation is essential for avoiding wasteful downtime.

Some form of machining simulation is available in a number of CAM systems. However, many are limited in their support for the G-code that runs the machine, which is why Machinists Inc. utilized Vericut CNC Simulation software for accurate collision checking.

A benefit of NX for Manufacturing is the integrated machining simulation capabilities in NX. For Machinists Inc., utilizing this feature eliminated the need to export the machine code and repeat much of the programming process to set up a digital simulation in Vericut, which further reduced programming times.

NX’s ability to talk directly across CAD and CAM gives NX an edge. The time savings of not having to program back in data lost in translation is measurable and frees up the team to focus on direct revenue-generating activities.

To get up and running, Charles worked with Hank Boehmer of Applied CAx to develop numerous post and sim kits for their machines.

Siemens NX for Manufacturing: All in One System Integration

Previously, to get to the finish line, Machinists Inc. was using three different applications for their machining, from three different companies. They had Solid Works for design; SurfCAM for programming, and Vericut for simulation. In addition to the cost of paying for maintenance and support for 3 different systems, (and dealing with 3 different software providers) when they encountered errors, they had to search through code in two separate platforms in order to troubleshoot and resolve the problem.

The migration to Siemens NX meant they could now do all their CNC programming in one system. In addition, when they do require technical support, the process is simplified as they only need to talk to one company. They’ve also no longer needed to pay for maintenance from three different providers.

Transition Training

Among the challenges in migrating to a new platform is getting employees trained on using the new software. To get staff up to speed, application engineers from Applied CAx came on-site to present a four-day hands-on training with the fifth day of CAD for CAM. From there, Applied staff came in weekly to supply mentorship and help with any issues that arose or questions.

One of the early challenges in transitioning came when things got busy and deadlines were looming.

According to Charles, “We initially found ourselves reverting back to old patterns early on due to the fact we got so busy and we didn’t have the time to stop production right then, so we had to use some of our old tools to be able to process and keep going. But in the meantime, we were trying to use the tool, and the mentorship was great plus the training… we have some good programmers here that were able to absorb a lot of that information and were able to start to do more in the system.”

The challenges in adopting new processes

It can take some time to fully adopt any new tool to the point where the capabilities of the software and the return on your investment are fully realized. As Charles discovered, when production schedules became hectic, some staff were initially still utilizing the old software due to the time and bandwidth needed to learn the new tools. But each time a team member reverts back to the old toolset, you lose money — after all, the investment in software has been made and was made for a reason.

No one becomes an expert in a new software platform in just a week. The mentorship program at Applied helps solidify the knowledge and the training curriculum, focusing on working on customer parts and practical applications to improve workflow and processes.

Follow-up and support is key to learning the new feature sets in the new environments.

“It can be a bit of a rough transition, moving from one software package to another, but the team at Applied CAx has been there for us to really help with their support” — Charles Stangland, Programming Manager at Machinists Inc.

Thanks to Machinists Inc. for teaming up with us to share their story in this case study. Visit their site at MachinistsInc.com