Standards covered:

- AIA_NAS for aerospace fasteners

- ANSI Inch & Metric

- DIN – German

- DLA – Defense Logistics

- GB – Chinese

- GOST – Russian Federation

- ISO – International Standards

- JIS – Japanese Industrial

- SAE – Society of Automotive Engineers

- UNI – Italian Standards Organization

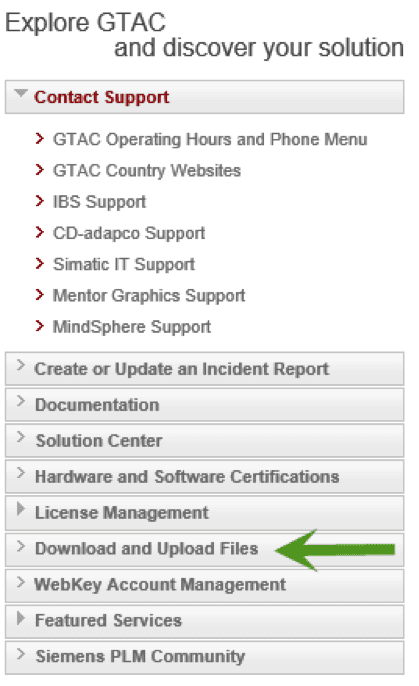

The Machinery Library can be accessed from the Siemens PLM Global Technical Access Center (GTAC) downloads site where you will be prompted for your login information. If you do not have a WebKey, click the link to WebKey Account Management and follow the instructions.

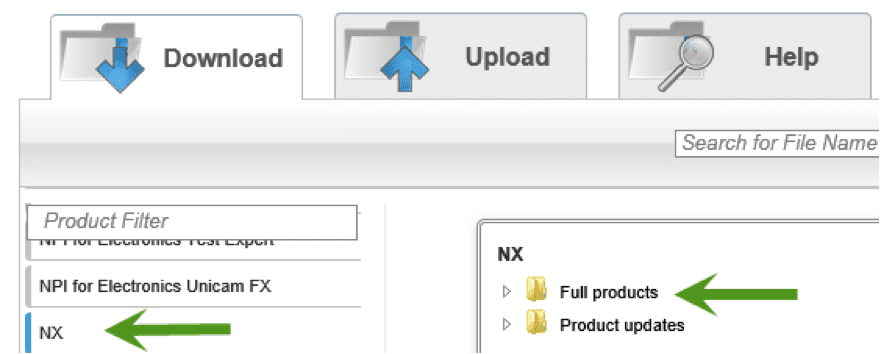

Once logged in, you will be taken to the Siemens PLM Download Server. The available downloads are linked to your license file. On the left column, locate NX then Full Products.

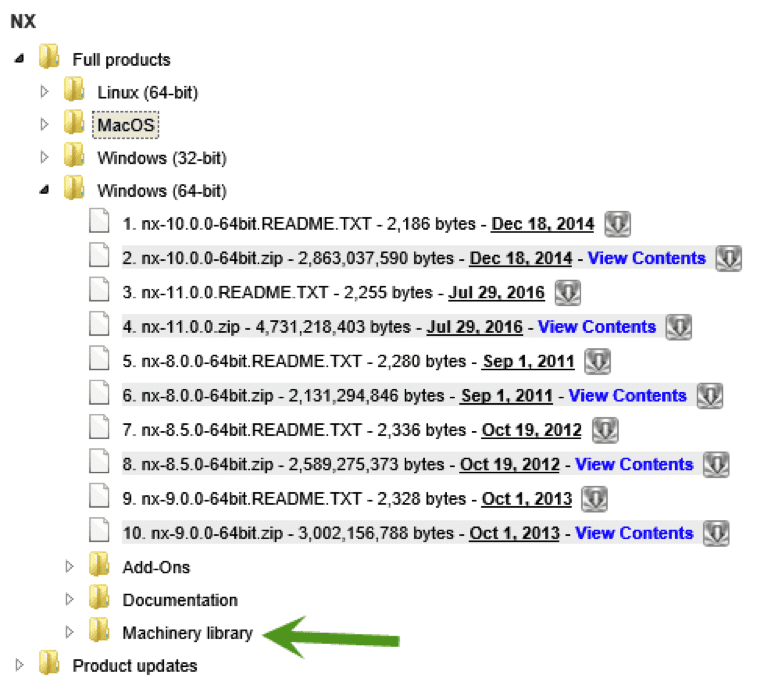

Expand Full Products and locate Windows (64-bit) and expand. Near the bottom of this list you will find Machinery library.

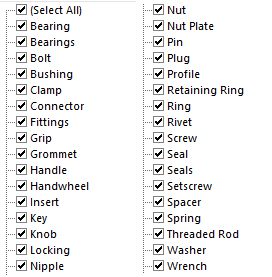

You likely do not need or even want all of the standards provided however, each standard does have different templates to draw from. We recommend that you download the Machinery-Library-readme.doc and the Machinery-library-catalogue-for-NX502.xls to help identify the standards you want to download. Filtering the catalogue on Category, you can see the available types.

Next, you’ll want to download the following:

- Free_NX_Machinery_Library_Install.doc

- Machinery-library-install-tool-2015-12-14.7z

- Fastener_Assemblies_Best_Practices_v1.docx

- Plus any standards you have decided to install. ANSI Inch & Metric being the most common.

Note: Some of the “zip” files are using 7zip file extension 7z.

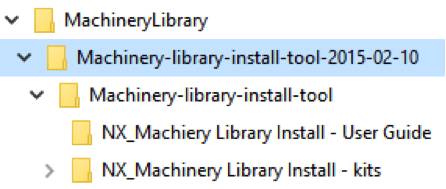

You will first want to unizip the Machinery-library-install-tool-2015-12-14 in a suitable location. Open the MachineryLibrary directory to find the NX_Machinery Library Install – User Guides for both Native and Managed or Teamcenter modes.

The installation guide provides all of the necessary instructions to install the libraries.

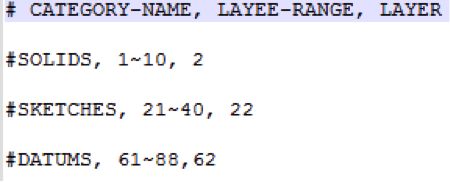

Note: If your organization uses Layer Standards and named Layer Categories, you have the ability to edit the MachineryLibrary-utilites.def file to match your organization’s standards. The file is filled out with a small subset of common layer categories and target layers.

Where the 1~10 are the layers in the SOLIDS category and the 2 is the target layer for the solids in this library.

Where the 1~10 are the layers in the SOLIDS category and the 2 is the target layer for the solids in this library.

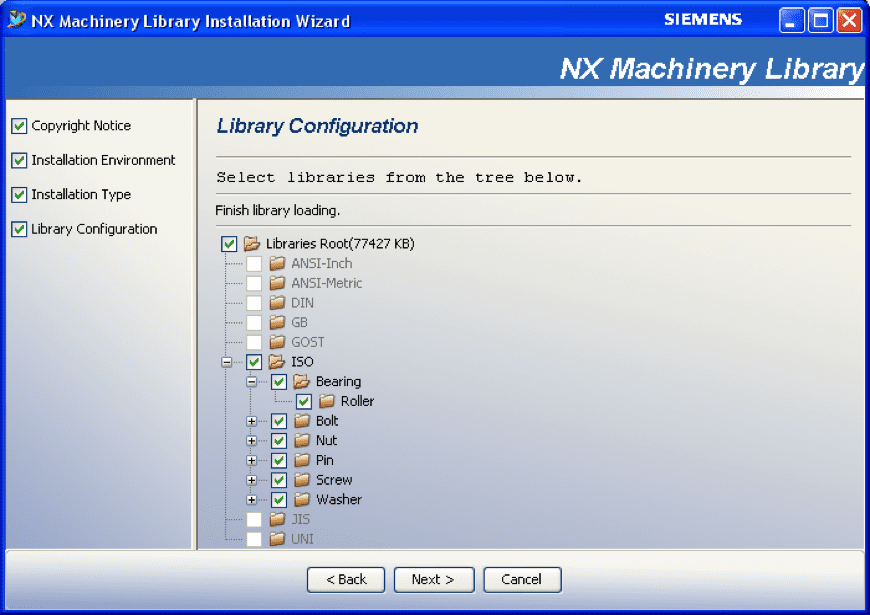

Once you have configured the Machinery Library Install tool, launching the MachineryLibrary-Installation.bat file will get the process started. You will be prompted to provide location for the library as well as the location of your NX install. If you have decided that you do not want certain objects contained within the standards you have downloaded, the Library Configuration page allows you to uncheck the objects you don’t want to install. For instance, if you already have your own library of common bearings, simply uncheck Bearing and this template will not be installed.

This install tool can also be used to upgrade an existing installation.

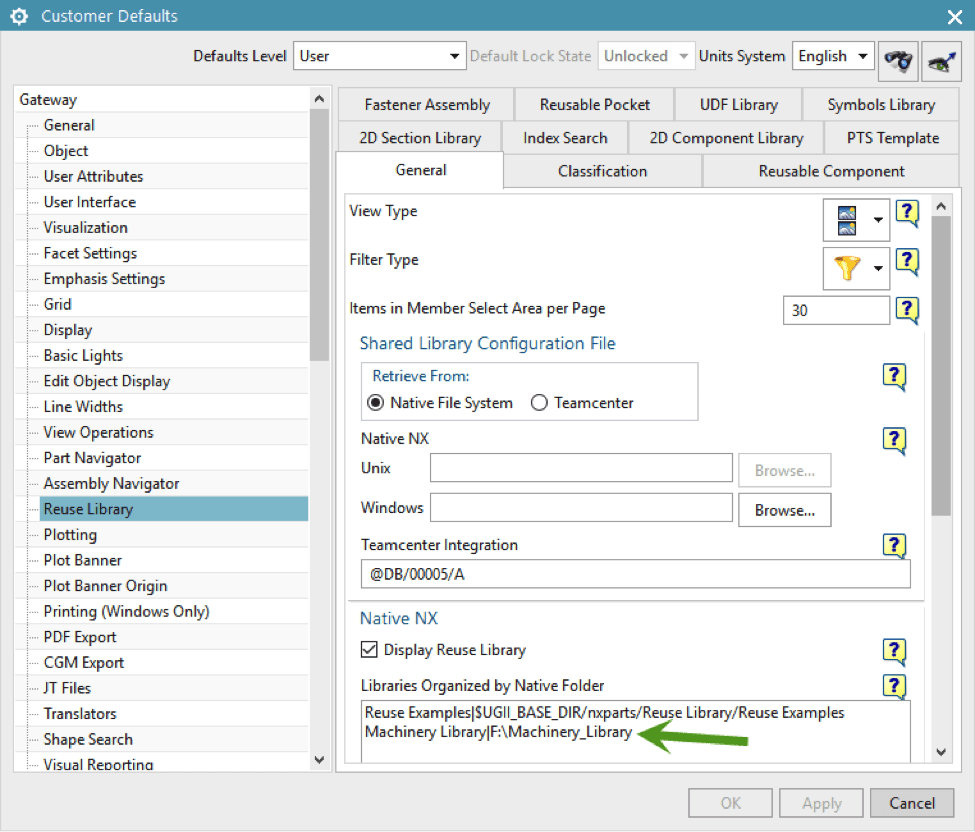

For those running NX in a Native environment, we recommend installing the machinery library in a network location accessible by all users instead of installing on each client machine. Setting the location of the Machinery Library in Customer Defaults is an easy way to set this library up for all users. You will find this in Customer Defaults > Reuse Library > General tab.

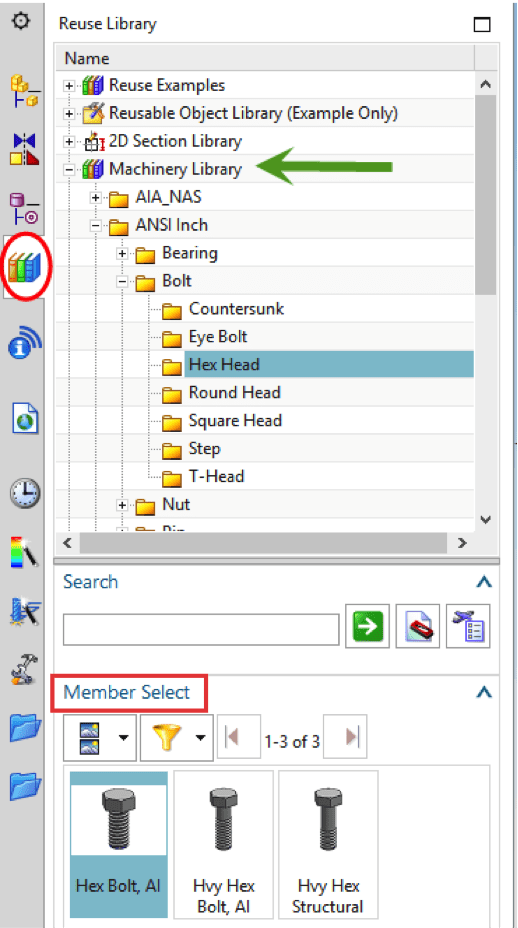

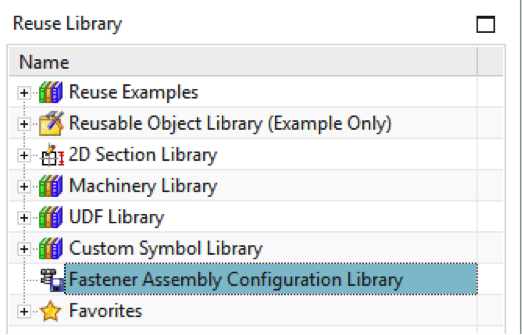

What the Siemens Machinery Library looks like to the end user when properly installed and configured.

Open the Reuse Library in the Resource bar to find the name you gave the library in Customer Defaults. Expanding each node until you get to the type of fastener or template part you want to uses.

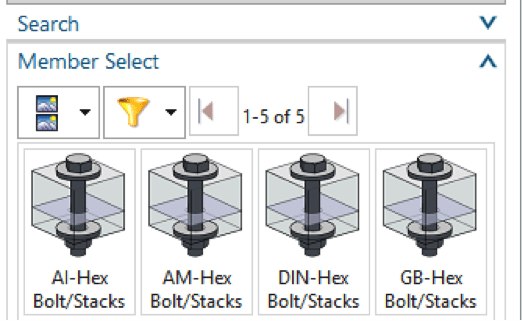

Note: Member Select is collapsed in a new installation.

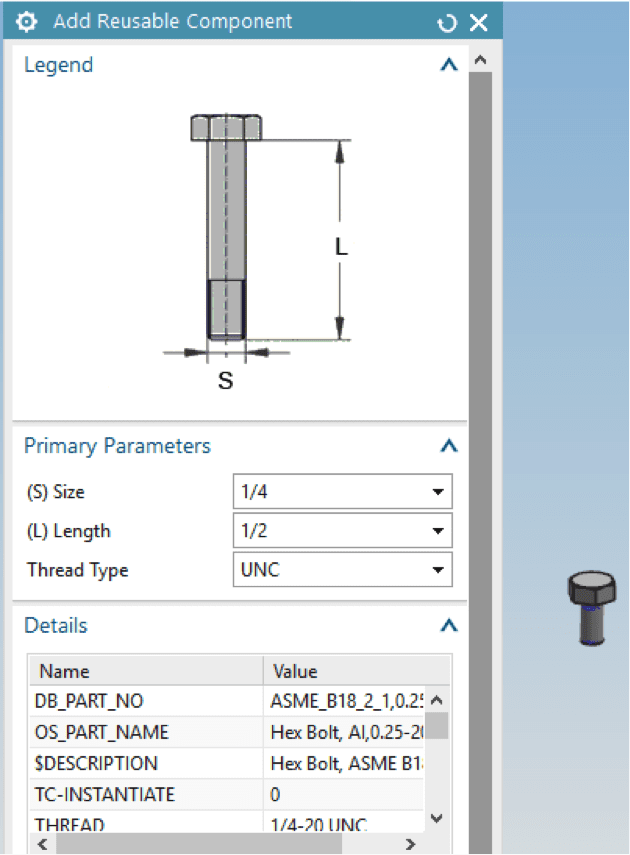

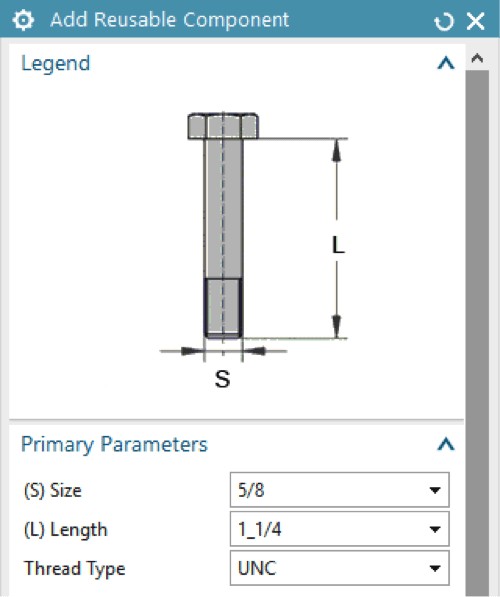

To use the template in your assembly, simply drag and drop it into your assembly. By dragging to an open space, you will be prompted to specify a size and length of the fastener.

Here you can access all of the available sizes and lengths in the library part.

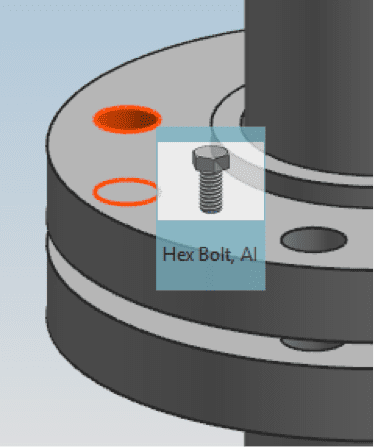

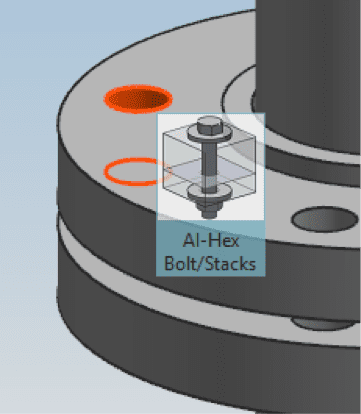

Conversely, if you drag-and-drop the fastener to a cylindrical face, the size of the fastener is inferred based on the size of the cylindrical face.

The fastener size has been selected however, you will have to adjust the length of the fastener based on need. The fastener will not “see” the opposing face nor will it automatically create the length you need as you may have differing requirements for the bottom side fasteners. I.E. flat washer, lock washer, nut, etc.

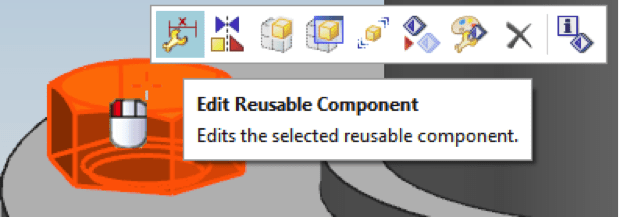

Once placed, you can Edit Reusable Component by left mouse button on the component and selecting from the shortcut popup.

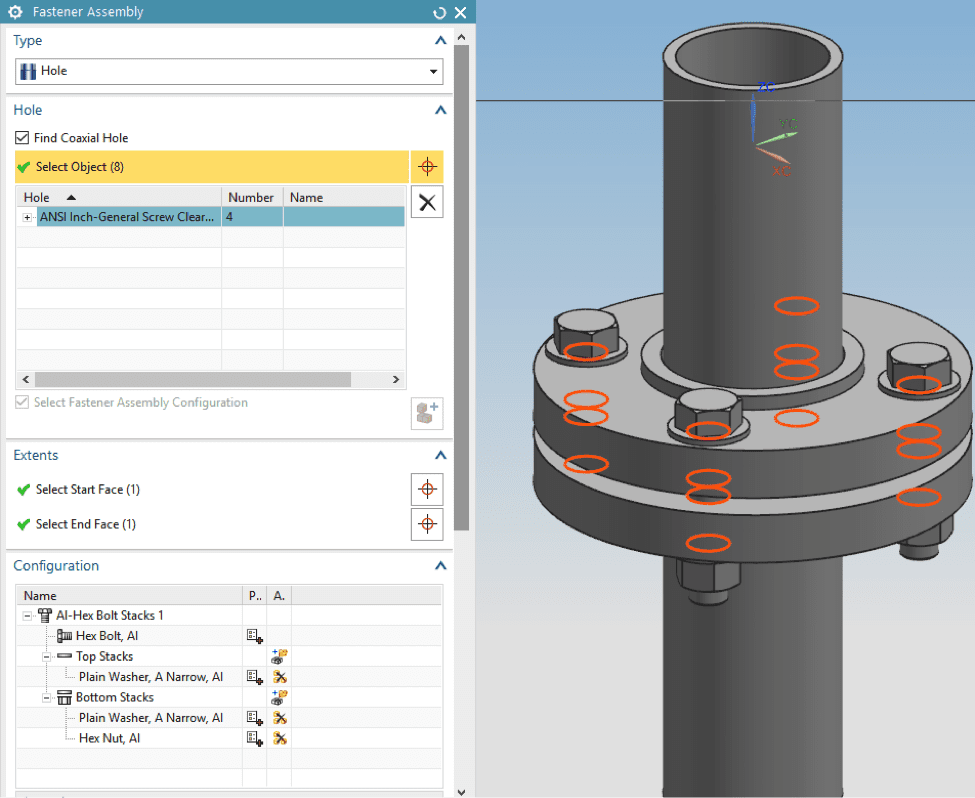

Fastener_Assemblies_Best_Practices_v1.docx explains how to configure your own “Fastener Assemblies” or bolt stacks.

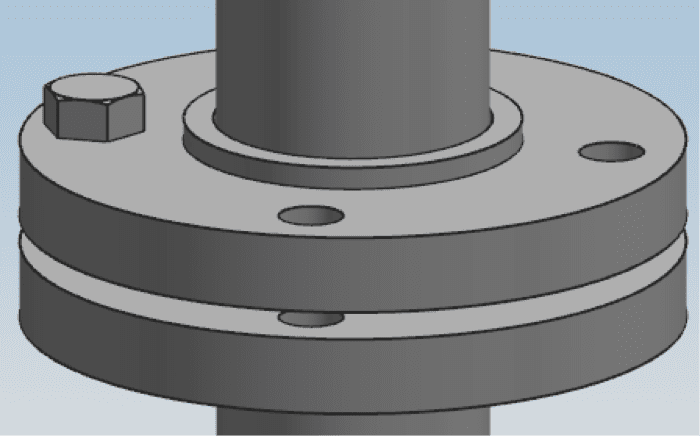

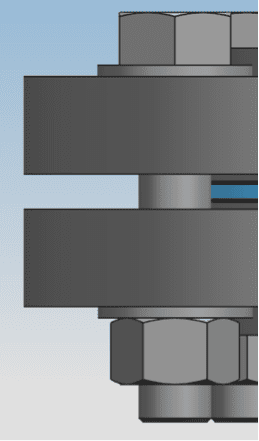

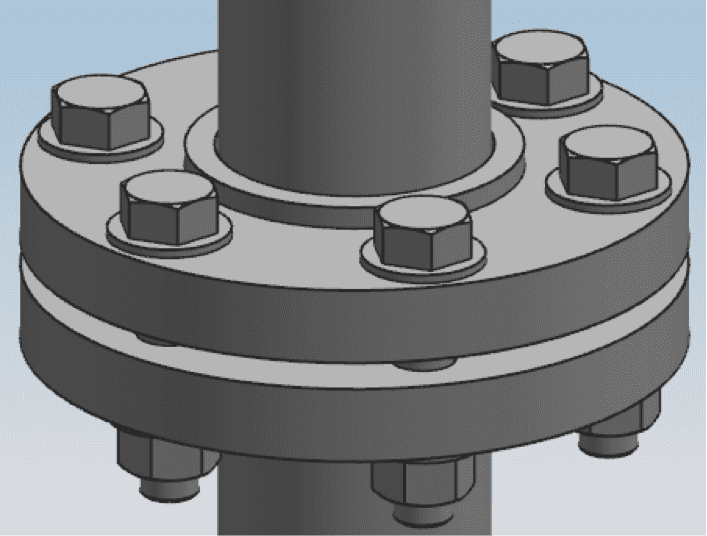

You can save significant time by configuring Fastener Assemblies for your users. Drag-and-drop a bolt stack from Member Select to a cylindrical face.

A Fastener Assembly can be pre-configured and adjusted on-the-fly as needed. It will automatically pick up and pattern component when it encounters a patterned feature in the component part.

If the pattern changes, the component pattern updates.

Contact us at AppliedCAx if you have any questions on downloading and configuring the Free Machinery Library from Siemens.