Since 1941, Machinists Incorporated (MI) has solved machining problems by creating single components to complete manufacturing systems. With experts in engineering, precision gears, machining, and welding, MI serves various industries, including aerospace, energy, transportation, and maritime.

Located in Seattle, Washington, MI is the largest precision machining shop in the Northwest. It maintains five plants with over 250,000 sq. ft.

To keep up with growing business operations, MI sought out more efficient and integrated computer-aided manufacturing (CAM) software.

The challenge

MI had a wide range of machines to support its customers but struggled to use them fully due to outdated CAM software for programming. The older software could not manage the complex kinematics of MI’s advanced machinery, such as the FPT Verus 250 high-performance 5-axis machine, which led to compatibility issues and operational complexity.

These limitations caused time-consuming and error-prone delays because the software lacked essential features such as volume checks and support for machine tools. This hindered MI’s programming efficiency.

Additionally, MI relied on three separate systems from different companies for design, programming, and simulation.

These challenges led MI to search for a CAM package capable of meeting its expanding business needs.

The solution: Siemens NX

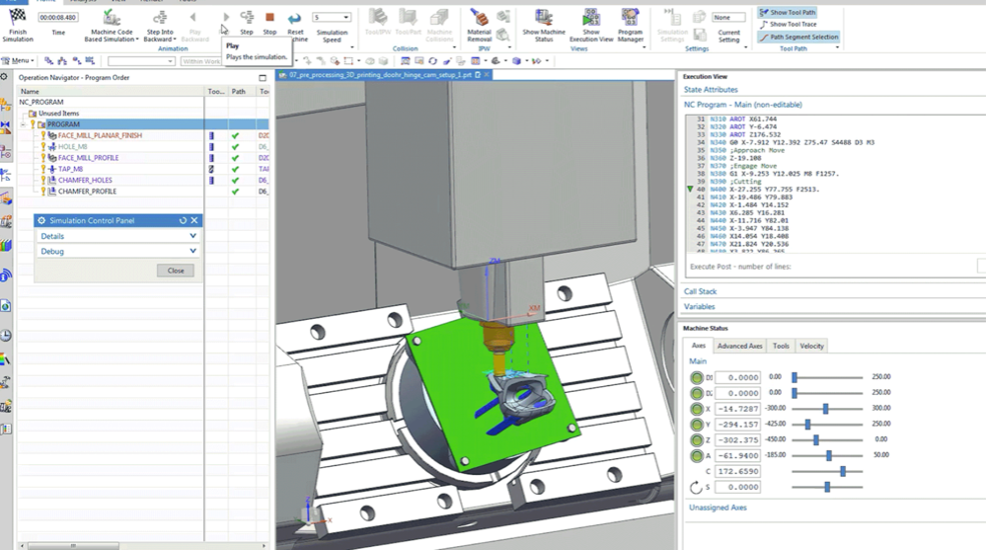

After an extensive search with various software packages, MI chose Siemens NX. This solution stood out for its ability to support more machines and assist with more data management than the competition. With NX CAM, MI could integrate all its design, programming, and simulation processes into a single, unified platform.

“NX is the software that supported everything from top to bottom. We could get mill-turn support, support on our 5-axis, and very intricate code. [We] could also get rudimentary code that worked on older 3-axis boring mills,” MI CNC Programming Manager Charles Stangeland said. “At the end of the day, that’s what drove our decision toward NX.

Transitioning to NX

Landing on NX introduced MI to Applied CAx, a Siemens partner that provided technical support during MI’s transition. Applied CAx came onsite to demonstrate the 5-axis abilities of NX CAM. During this visit, MI was able to directly see how NX would process parts and integrate with current and future tools.

After that initial day, Applied CAx helped weekly to supply mentorship by developing post and sim kits and assisting with any problems or questions.

“It can be a bit of a rough transition, moving from one software package to another, but the team at Applied CAx has been there for us,” Stangeland said.

Even though operations were improving because of NX and Applied CAx, MI still faced setbacks during the transition process.

“We initially found ourselves reverting to old patterns early on due to the fact we got so busy,” Stangeland said. “But we were trying to use the tool, and the mentorship was great—we have some good programmers here that were able to absorb a lot of that information and were able to do more in the system.”

Applied CAx’s mentorship and training were instrumental in motivating MI to fully adopt and integrate NX into its business operations.

Looking ahead

By implementing NX, MI has significantly reduced its programming times. The integration of NX automation tools has introduced new possibilities that streamline processes and enhance efficiency.

The ability to run simulations directly within the NX environment has eliminated the need for additional software, which has further simplified MI’s operations.

“Weʼre looking forward to continuing with Applied CAx as weʼre on maintenance and needing support—we will always need support. It can be a daunting programming system, but there is a lot of capability there, and we see it as the path forward in the future,” Stangeland said.