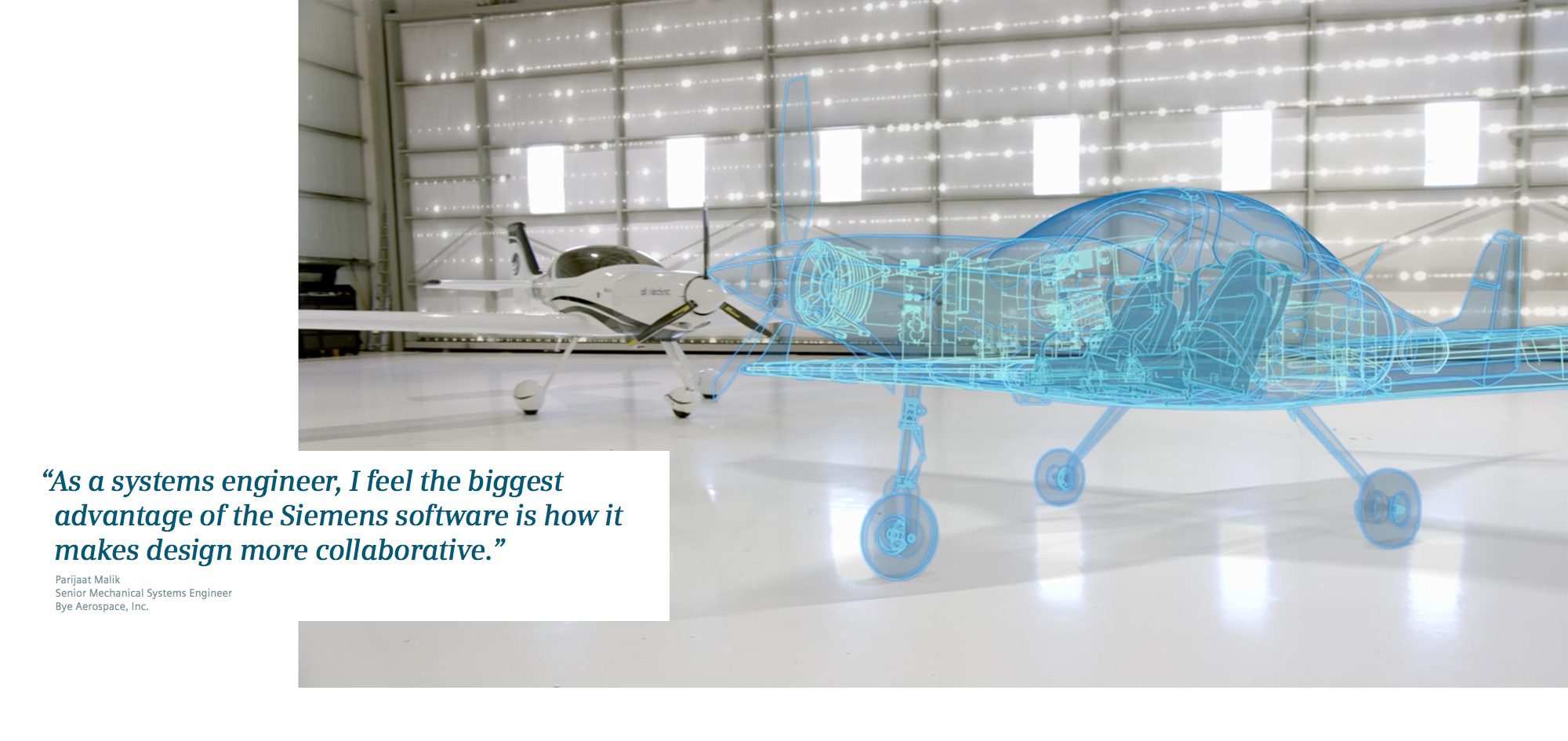

Bye Aerospace is an aviation start-up focused on creating innovative electric aircraft solutions. Their response to the high cost of new pilot training: an innovative, all-electric airplane dubbed the eFlyer. The firm also develops and integrates structural and mechanical systems along with aerodynamic advances in design, building products that offer significant cost benefits and improved performance.

With two electric aircraft projects underway in the Federal Aviation Administration (FAA) 14 Code of Federal Regulations (CFR) 23 aircraft certification process, the first and most important is the eFlyer 2 training aircraft. According to founder and CEO George Bye, “What’s disruptive and changes the opportunity with electric aircraft is the propulsion system. The trajectory for electric motors and batteries and their evolution from 10 and 20 years ago to the present day makes it possible for the first time to develop an aircraft that is very disruptive, has lower operating costs, no Co2, and is very low noise. That’s the piece that changes everything.”

Being the first aircraft to certify with electronic propulsion to the FAR 23 standards, the aerospace startup is on the leading edge of certification. To stay on the leading edge, the Bye Structures Department has used several solutions from Siemens Digital Industries Software to help them get off the ground, most notably the Fibersim portfolio and NX software.

A “technology enabler”

Fibersim is used to optimize the structural integrity of the composite air frame, and NX to develop the outer shape of the plane. Fibersim is used to build up the layers of composites from the outside in.

They also use Teamcenter® software for product data and end-to-end management, SimcenterTM STAR-CCM+TM software for computational fluid dynamics (CFD), Simcenter 3D software for analysis, testing, and certification, and CapitalTM software for wire harness and layout. Using these five products, which are part of Xcelerator, a comprehensive and integrated portfolio of software and services from Siemens, has enabled Bye to create a seamless end-to-end process.

“The reason we use NX instead of another CAD system is because it has a more seamless transition from design to analysis, which gives us more time to do more iterations on our design,” says Parijaat Malik, senior mechanical systems engineer. “We’re able to easily make a few changes and analyze that design and just make the changes that we need to make that particular design work. Also, one of the biggest things NX provides is wave linking, which makes parametrizing assembly so much more robust than any other CAD software that’s available.”

The small team leverages the Siemens software platform to reduce product development time while doing more iterations with a relatively small team. “We have 20 people on the engineering team. A typical company would have 50 to 60.” says Tom Bowen, Chief Engineer. “The reason we can do that is because Siemens software is so integrated that you don’t need the traditional specialists.”

“The NX CAD software in particular that we’re using right now is a technology enabler. It keeps Bye Aerospace in front,” says Bye. “The ability to capture all of the aspects of an airplane design is greatly enabled. In capturing the eFlyer 2, Siemens software is particularly capable of helping us to transition to what comes next.”

Interested in working with us? Click here to read more about our work in the Aerospace and Defense Industry.