PacMar Technologies is a leader in developing cutting-edge products and solutions for the defense and maritime industries. Helping customers take an idea from a concept to a sea-ready physical prototype, they model, simulate, and construct novel systems for the Department of Defense and other partners.

For companies like PacMar Technologies, leveraging simulation software tools is an integral part of their product development design cycle. Utilizing advanced simulation reduces cost risks for their customers in the development process, and allows their engineering team the ability to conceptualize innovative design solutions that weren’t possible with the previous design cycle model.

Advantages of Virtual Prototyping in Product Development

The use of digital simulation tools has transformed the marine industry, and computational fluid dynamics (CFD) has been the backbone of engineering efforts at PacMar Technologies.

Designing anything that moves through or under the water requires the ability to understand the hydrodynamic benefits or consequences of the design. Traditionally, the marine industry has relied on physical testing using scale models in towing tanks or empirical relations such as the Savitsky Method for ship performance predictions. Both of these alternatives have drawbacks; creating physical prototypes is both costly and time-consuming due to the stringent requirements and high tolerances. And empirical methods aren’t known to result in novel innovations.

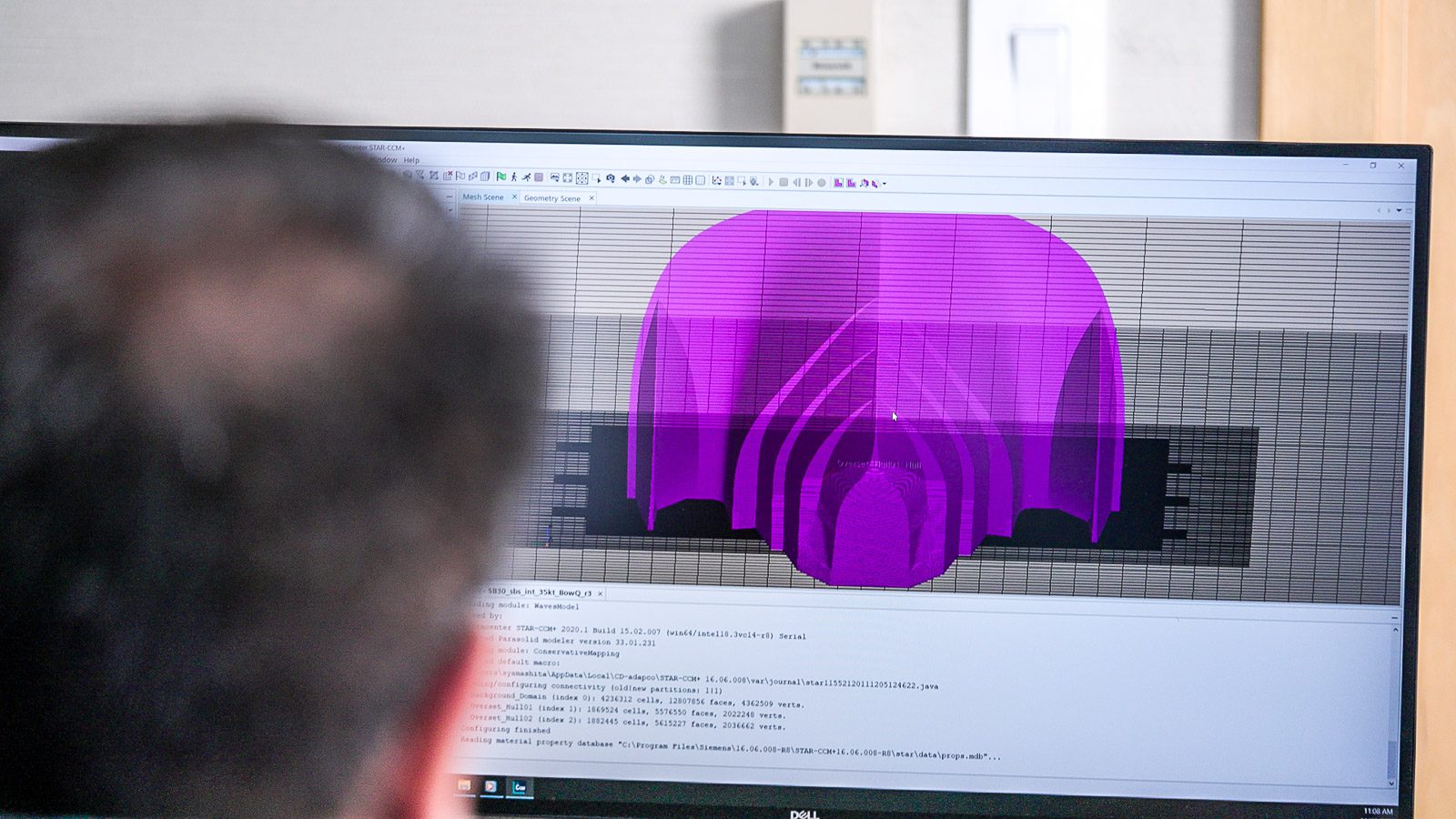

By routinely using Simcenter STAR-CCM+ to produce quantitative predictions, the engineering team at PacMar Technologies is able to gain insight on an initial design of the outer lines of a vehicle. Conducting simulations to assess the hydrodynamic performance, they’re able to make design modifications to ensure they meet the necessary performance metrics. Engineers can refine their designs, fine-tune dozens of iterations of products, and test performance in a virtual environment before progressing to constructing a physical prototype.

Innovation on a Level That Didn’t Previously Exist

With the high product development costs, many programs wouldn’t be able to move beyond an initial design without simulation.

The use of advanced CFD simulation allows PacMar Technologies to predict and troubleshoot issues, mitigating potential risks during the design phase, reducing the likelihood of failure or costly product recalls.

Reducing the risk involved with the high cost of prototypes has produced innovation on a level that didn’t previously exist. The team at PacMar Technologies has developed a number of novel designs they’ve patented, including a completely re-imagined deep V hull design, which resulted in the Sea Blade line of watercraft.

“

Using tools like STAR-CCM+ enables us to take those risks and innovate in the marine industry. We’ve received a variety of patents, and they’ve provided a lot of value to PacMar Technologies because innovation in this industry has become what we’re known for.”

— Scott Yamashita

Director of Naval Architecture

PacMar Technologies

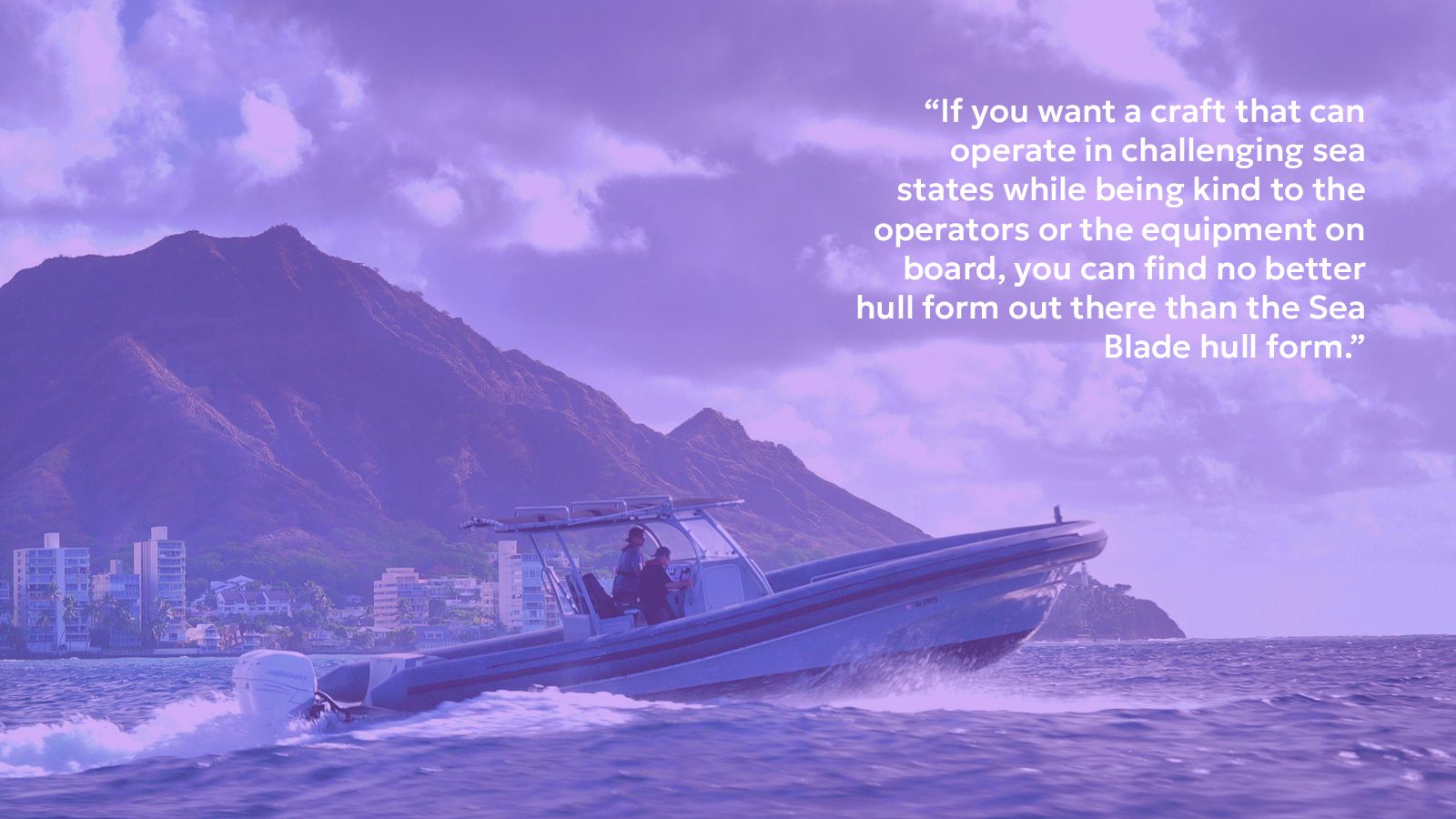

The Sea Blade Hull Form

The Sea Blade hull is one of PacMar Technologies’ most successful surface ship programs. A reimagining of the classic deep V hull, its unique hull form is unlike any other on the market.

Internally, the team refers to it as their entrapment tunnel monohull craft design. The unique design features a stepped hull that has a series of vertically spaced longitudinal steps that enable it to provide high planing efficiency, but also controls the impacts that an operator takes when operating in waves.

The entrapment tunnel technology improves direction stability and course keeping, and reduces excessive rolling, yawing, and heeling. Trapping air and water, it increases planing lift and reduces hull drag, reducing fuel consumption.

It also dampens the boats reentry into the water by acting like shock absorbers, reducing slamming, pounding, and plunging. The deeper, stepped hull better penetrates waves and reduces stress on passengers, packing the offshore performance of a larger boat into a compact, efficient, trailerable package.

“

One of the designs that Pacmar Technologies is very proud of is our entrapment tunnel monohull craft design, commercially known as the Sea Blade hull. It is a high-end, high-performance craft. If you want a craft that can operate in challenging sea states while being kind to the operators or the equipment on board, you can find no better hull form out there than the Sea Blade hull form.”

— Daniel Brunk

Chief Executive Officer

PacMar Technologies

Benchmark Comparisons: the Sea Blade vs a Deep V

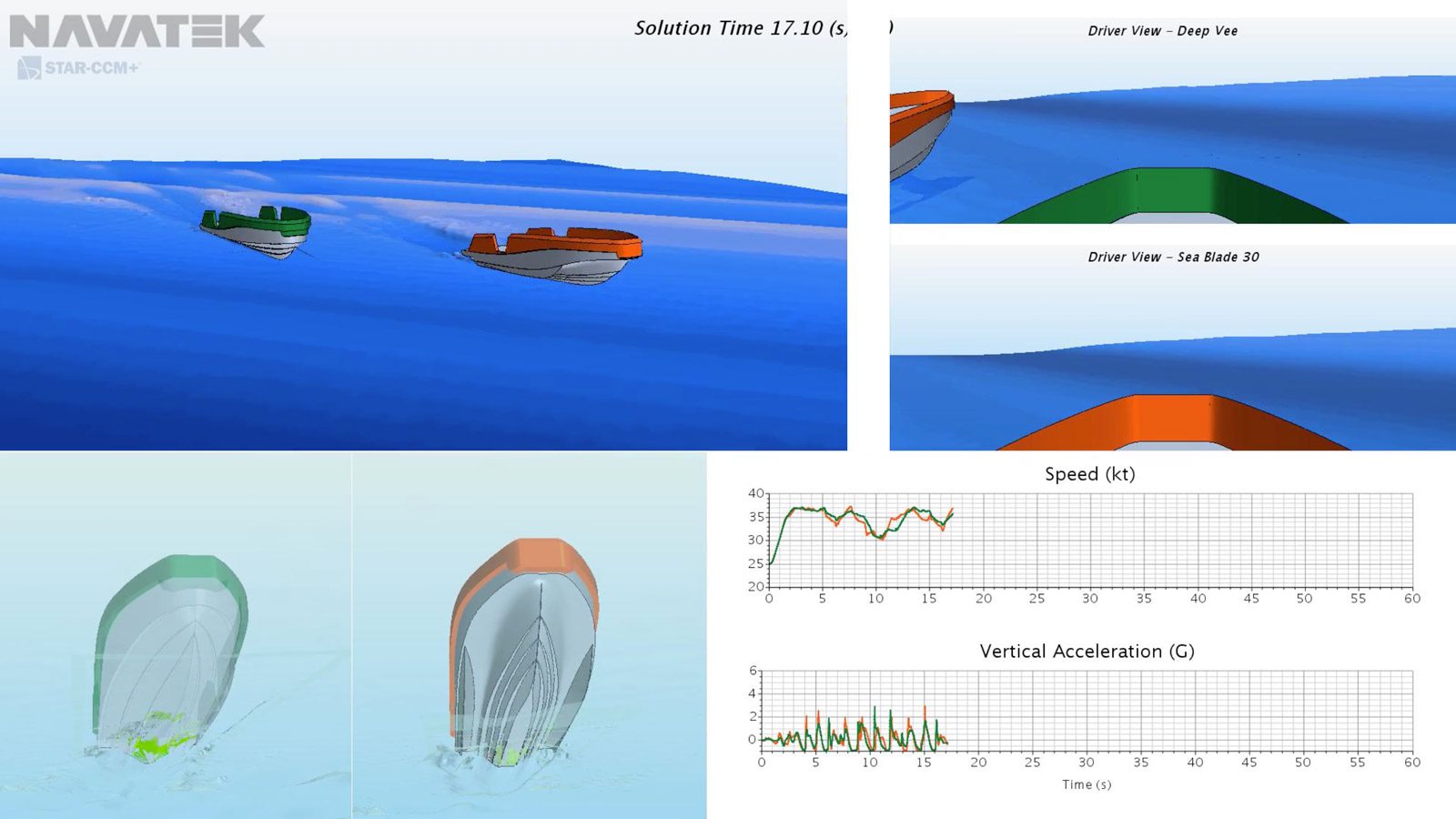

As the team developed the entrapment tunnel design, they utilized CFD to benchmark design iterations against other traditional hull designs. The most comparable is a Deep V hull design.

Using STAR-CCM+ to perform simulations of the two designs head-to-head, they not only showed up to 2 knots more in speed but also a 23% reduction in slamming and a 50% reduction in roll response. After being satisfied with the reduced risks of the new design, they moved forward to developing a physical prototype, and performed tests in the sea to validate their predictions.

Compared to the Deep V hull, the Sea Blade design was faster to plane and offered enhanced pitch control. The reduction in slamming and shock g-forces resulted in less operator fatigue. It also provided a more balanced ride, with reduced yaw, improved tracking, and speed control. In addition, the new design offered improved fuel economy.

Developing a Novel Hull Technology

Without the company’s use of CFD simulation, the Sea Blade hull design never would have been developed. Scott Yamashita, Director of Naval Architecture and Marine Engineering, has been doing CFD analysis for over 15 years and is one of the principal investigators at PacMar Technologies. Scott explains:

“The Sea Blade hull form is unique and truly different from any other boat on the market. It uses a combination of panels and features to provide a highly efficient and stable platform with superior impact damping when running in open ocean waves. These patented features have been painstakingly studied and refined using STAR-CCM+.

I don’t know if we could have found its unique hull form through any other method. You’re just trying to take a risk and try something new. You look at the boat, and you’d never design a boat that way. But we did, and it works.

The best boat on paper doesn’t mean anything if it’s not the best boat on the water, right? We did physical, full-scale testing to validate our STAR+CCM+ simulations and found a strong correlation to what happens in the real world. What the software provides us only gives us more confidence to push our designs using STAR-CCM+.

One of the best compliments we ever hear when we take people out on that boat is when you launch off a wave, and you come back into the water — they keep saying, you know, they’re bracing themselves for the slam that never happens. CFD simulation is what enabled us to unlock the secrets.”

Read more about the SeaBlade line of boats here.