How does an enterprise-level company adopt a new CAD technology while maintaining backwards compatibility with suppliers, yet still reap the benefits without micromanaging their supply chain?

It’s a difficult juggling exercise, but as adoption of new CAD technology takes place within an enterprise, there are often growing pains. Different segments of supply and resource chains adopt the technologies at different levels of urgency and commitment. Vendors and suppliers do not always have the same resources or technological approaches as an intrepid enterprise-level company. These differences risk creating friction points that diminish the efficiency improvements afforded by your technology upgrades.

By using model-based approaches, companies can simplify their approaches to file management with fewer files; companies can spend less time fine-tuning drawing layouts for visibility; companies can also start to use PMI with downstream products and applications to reap benefits far beyond what happens in CAD (automated CMM programming, simplified PLM, data-driven approaches).

Not all suppliers have fully adopted MBD or PMI, so when it comes time to send designs out for prototyping or production, they may encounter friction points – suppliers may not have CAD or CAD licenses that support this increasingly common approach. How do adopters of PMI interact with companies that aren’t able to open or view parts with PMI? How do they send a part with PMI to a shop that only works with parts and prints, and how do they do it without spending large amounts of time creating a completely redundant print?

Siemens NX is complete with features that can assist your company in adopting new CAD technologies while maintaining a level of compatibility critical to the transition period. We’ll explore an example in communicating PMI and GD&T, and how NX’s Technical Data Package export feature allows companies exploring Model-Based approaches to still work alongside vendors that have not yet fully adopted MBE (model-based enterprises) or MBD (model-based definitions).

NX has the ability to create 3D PDFs, viewable in the latest free version of Adobe Acrobat, which can display PMI objects and annotations. The file is created as part of the Technical Data Package feature in NX, which supports a broad range of manufacturing and product related information.

By using these files, your company can also start to inspire vendors and suppliers that are part of the enterprise-level effort to experience the benefits of emerging CAD technologies.

These files are automatically generated and are compatible on software stacks that don’t necessarily explicitly support PMI. These files display all PMI objects selected by the user and have options to improve readability. These files can be sent to vendors, who can then rotate and view the PMI objects in the context of the 3D part geometry, all without spending extraordinary time creating a 2D print just for the shop that can’t use PMI. By using these files, your company can also start to inspire vendors and suppliers that are part of the enterprise-level effort to experience the benefits of emerging CAD technologies.

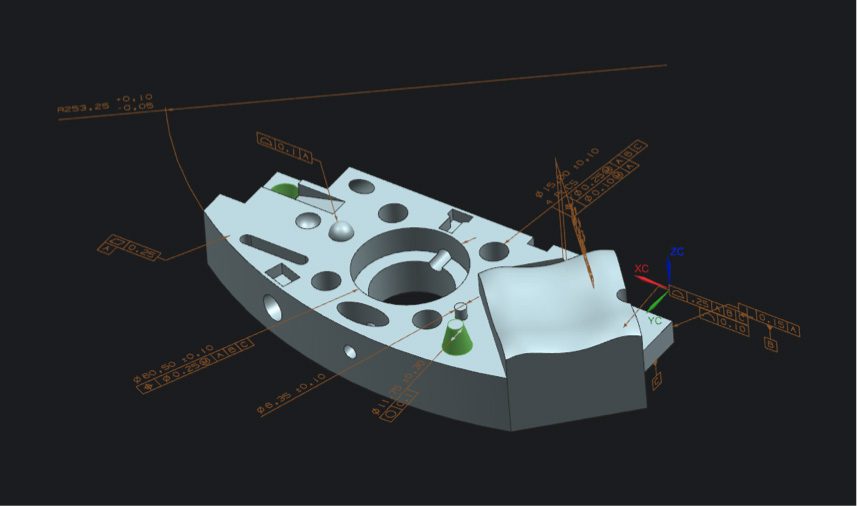

To create these files, simply open up your part with thoughtfully prepared PMI ready to go. In this example, also note that we have PMI objects associated with and displayed on a variety of planes.

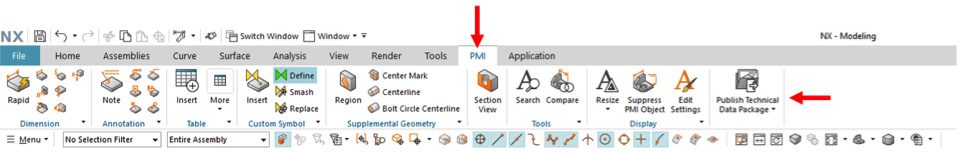

To provide all of this PMI to a vendor who does not explicitly have a CAD program that supports PMI, simply head to the PMI tab, and click on Publish Technical Data Package

From there, you must decide what size/orientation you’d like your 3D PDF to take (paper size versus landscape/portrait). You can also which model views you’d specifically like to export (if there are any you’d like to exclude). In the screenshot below, I’ve selected 7 out of the 8 available views in the Part Navigator:

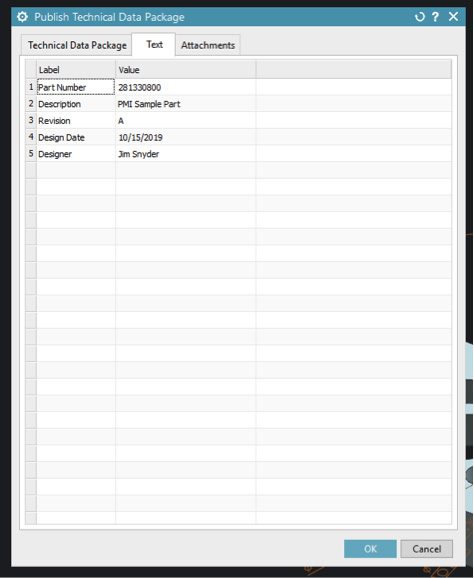

I can then add any basic information that is typically stored in a traditional 2D drawing’s title block in the Text tab:

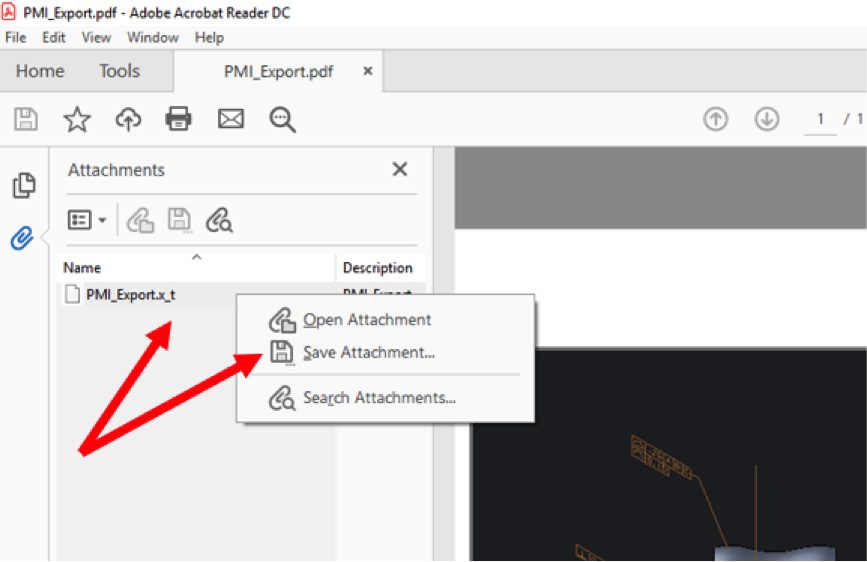

You can add any other files as an attachment to the 3D PDF, such as a BOM, a photo of the finished part, or anything else you find relevant to the informational export. This style of PDF supports attachments, so the output will always be a single file with the .pdf extension (supported by the free version of Adobe Acrobat).

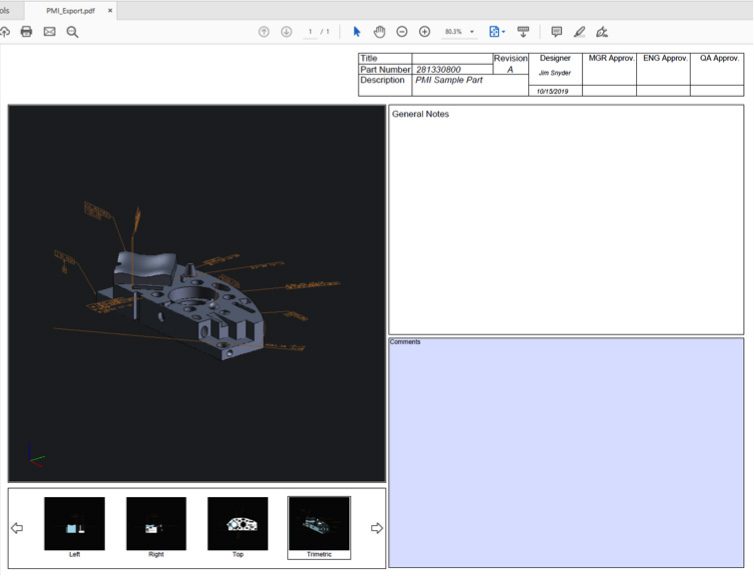

From there, click OK, and your 3D PDF will be prepared. Open the file in Adobe Acrobat Reader, allow 3D content, and you should be able to view a 3D model of the part, with PMI visible.

All of the selected views will be available as shortcuts below the 3D part display. Click on the name of one of the views and the part will automatically rotate to that view and orientation. The user can always rotate and zoom the model, it is still a 3D model. The user only had to select views and orientations, along with filling out a title block, everything else is handled automatically. Compared to making an entire print from scratch, these efforts are trivial and allow you to take advantage of PMI without significant work to maintain backwards compatibility.

There is an option to automatically export a standard (non-3D) PDF along with a JT file, which is a type of neutral CAD format, though the 3D PDF’s functionality is so useful in easily displaying PMI data automatically, that we recommend the following workflow to take the best features from all available approaches:

- With your part file open, export the part to any format compatible with your downstream suppliers (STEP, IGES, Parasolid, JT, etc); NX supports a wide variety of CAD-neutral file formats. Currently, most neutral formats do NOT support the storage and display of PMI data.

- Publish the 3D PDF technical data package and include the exported part file as an attachment.

- Delete the exported part file from step 1, it is now stored as an attachment in the PDF generated in the previous step.

- Send this PDF to your vendor, which will include all PMI, a 3D PDF that can be viewed on computers without CAD, and a part file that can be measured on computers with CAD.

With this approach, you’ll be able to automatically provide PMI data to suppliers without significant additional drafting work, you’ll be able to provide a neutral CAD file format, and you’ll be able to preserve a single file, model-based approach easily without significant backwards-compatibility provisions.