The new art of manufacturing – going beyond 3D printing

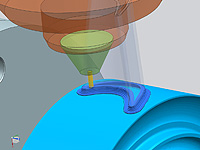

NX CAM is leading the industry with support for new hybrid additive manufacturing technologies, where additive manufacturing (metal deposition) is incorporated into a traditional machine tool environment. By building up complex geometries using additive manufacturing, including internal cavities, then machining them for tight tolerances as they are built using subtractive manufacturing, you can manufacture new classes of parts or consolidate many setups into one with this new hybrid additive manufacturing process.

- Prototype: Creating prototypes accounts for most of the 3D printing and stereo lithography processes to date. Allowing you to quickly evaluate prototypes will continue to be a strength of additive and hybrid additive technologies.

- Production: New laser sintering (powder bed) capabilities are moving manufacturers toward using additive manufacturing approaches for part production. The hybrid additive manufacturing techniques will accelerate this trend.

- Repair: By combining metal deposition and traditional metal cutting into one machine environment, possibilities for repair and refurbishment are wide open. Hybrid additive manufacturing is an ideal solution for this type of work.

Download NX Hybrid Additive Manufacturing PDF

Think It.

|

Model It.

|

Make It.

|

You are no longer held to the traditional constraints for component shapes. These new hybrid manufacturing techniques allow you to consider internal chambers and cavities previously out-of-bounds for part manufacturing.

You are no longer held to the traditional constraints for component shapes. These new hybrid manufacturing techniques allow you to consider internal chambers and cavities previously out-of-bounds for part manufacturing. Software guidance can be a big help when considering these new approaches to part manufacturing. As models are developed, additive and hybrid manufacturing techniques may require attention to thermal shrinkage or scaffolding for unsupported regions. NX has tools to help you produce part models ready for these new manufacturing methods.

Software guidance can be a big help when considering these new approaches to part manufacturing. As models are developed, additive and hybrid manufacturing techniques may require attention to thermal shrinkage or scaffolding for unsupported regions. NX has tools to help you produce part models ready for these new manufacturing methods. NX analyzes the model in order to optimize the additive deposition sequence along multiple build vectors, then provide the tool paths that build the component as you envision it. The hybrid machining technology lets you additively create features and immediately finish them to tight tolerances with traditional machining methods, so the part comes off the machine completely finished.

NX analyzes the model in order to optimize the additive deposition sequence along multiple build vectors, then provide the tool paths that build the component as you envision it. The hybrid machining technology lets you additively create features and immediately finish them to tight tolerances with traditional machining methods, so the part comes off the machine completely finished.