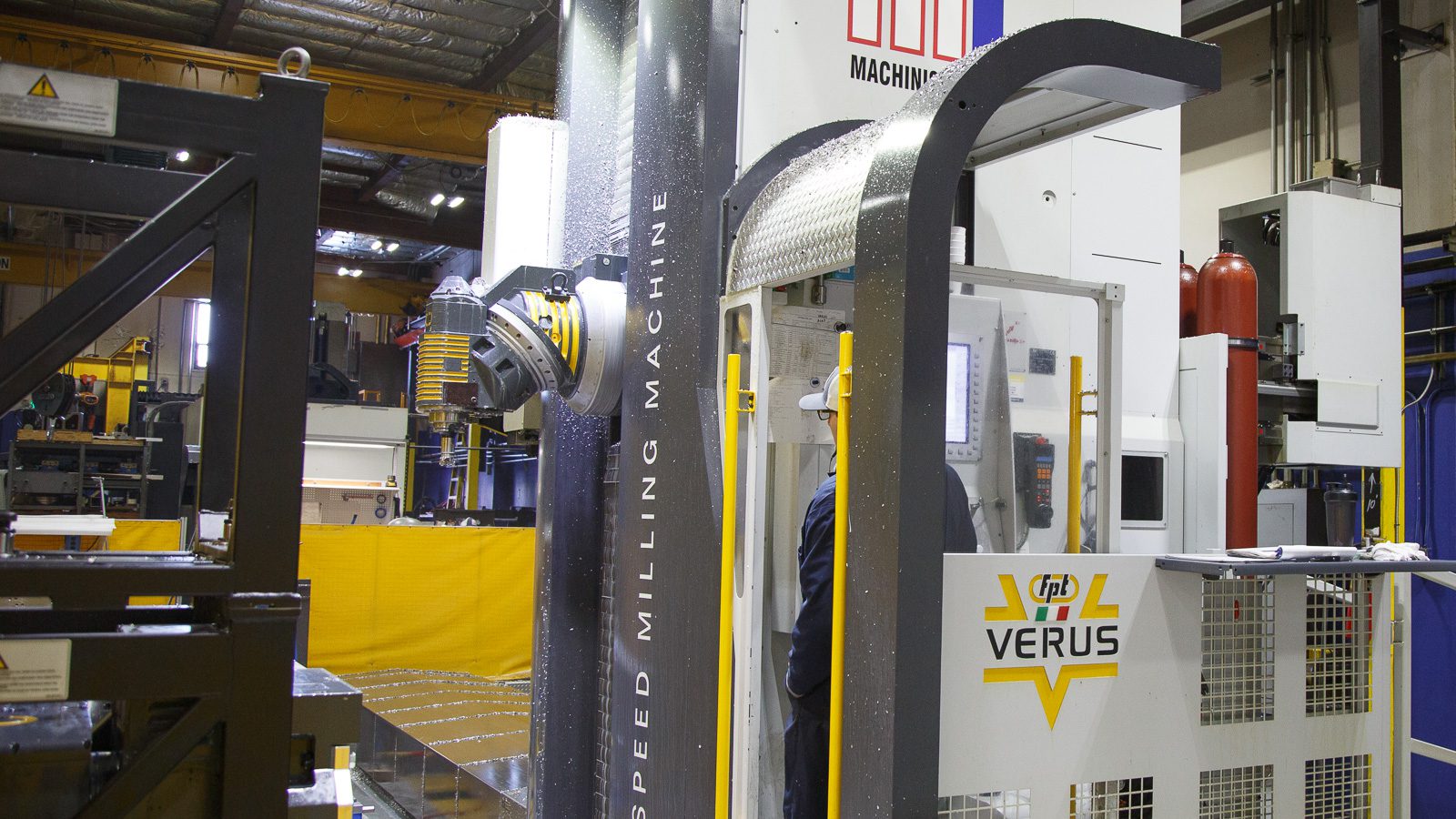

Machinists Inc is a job shop located in South Seattle that serves the maritime, aerospace, research, and transportation industries. With 7 plants covering over 250,000 square feet, they’re one of the largest precision machining shops in the Northwest. After two years of writing post processors with their former CAM software, it became clear they needed a better solution that could keep up with the investments they were making in their equipment.

In working machine shops, losing time is losing money. A business can’t afford to have machines sitting idle while a programmer is struggling to implement updates to code. While changing from what you’re accustomed to and migrating to an all-new software platform can be daunting, staying with a CAD/CAM tool that holds you back will also cost you — and it’s a hidden cost that adds up exponentially.

We recently worked with Machinists Inc. on their migration to the Siemens NX platform, assisting with training, mentorship, and technical support, as well as post creation. Along the way, we sat down with Charles Stangland, Programming Manager for Machinists Inc, to discuss what motivated the change to the new software solution, and the challenges they experienced along the way.

During our conversations, we discussed everything — from the roadblocks his team experienced with their previous CAM software, to how it instigated the search for a new CAM tool — as well as the process they went through in evaluating the options before selecting Siemens NX for their new CAM solution.

Why NX CAM?

Taylor Saul, Senior Account Manager at Applied CAx: How did your initial search begin? I know that you were looking at a lot of different tools. What led you to Siemens NX? I remember you also were working with the DMG MORI rep when you bought it, and he specifically recommended you were going to get more functionality out of that advanced Machine Tool.

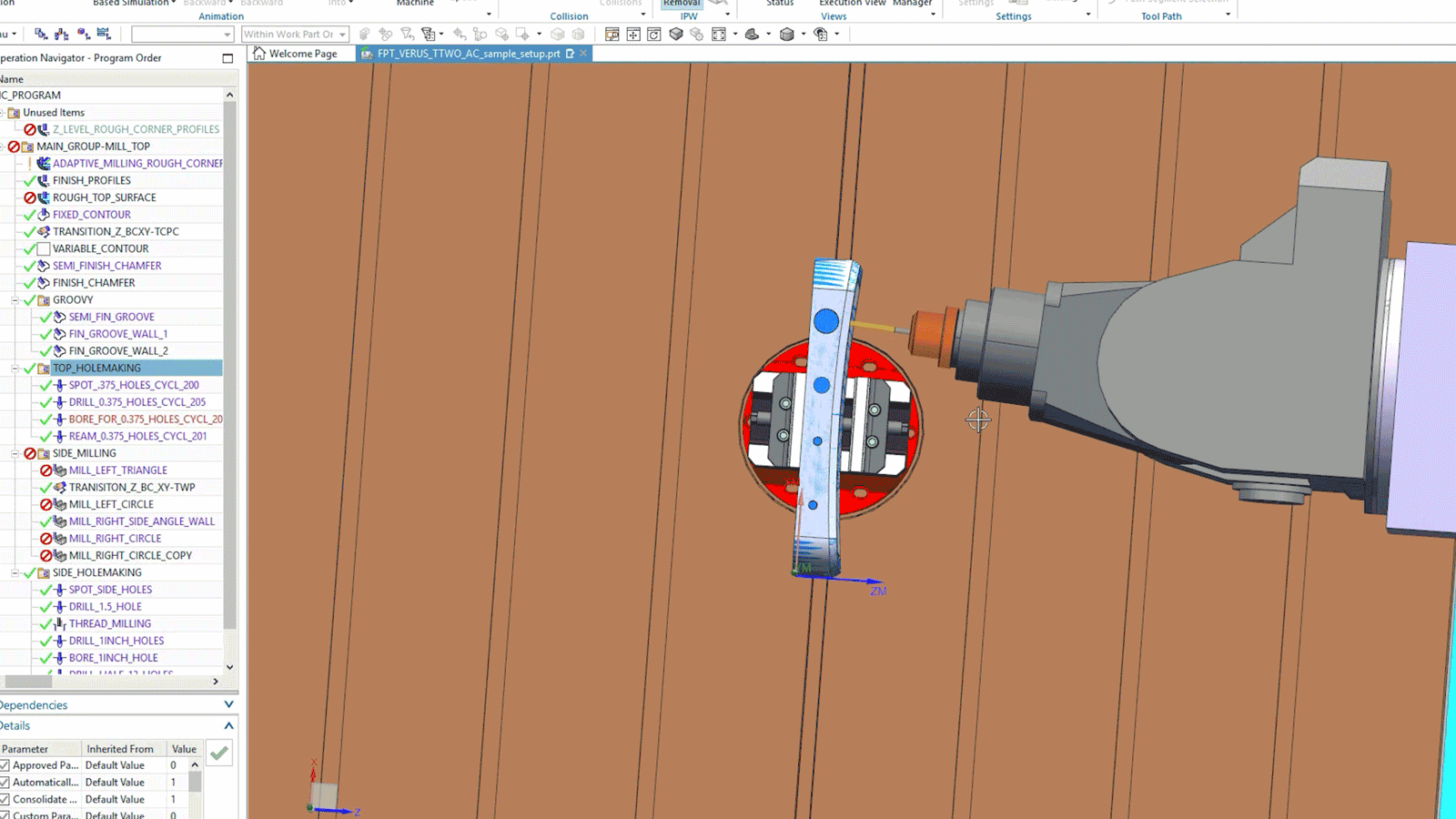

Charles Stangland, Programming Manager, Machinists Inc: When we took on the FPT Varys, we were using SURFCAM at the time. We figured okay, we’re going to have post processors written to support it and we’ll just keep on doing things the way we’ve always done them. It became pretty evident after two years of trying to write post processors for that machine that we were not getting to the finish line, and it was starting to force us into asking “What are we doing wrong?”

We needed to go out and look for a better tool to program these machines to utilize their capacities and their axis and their capabilities, you know, to the best of Industry. SurfCAM just wasn’t keeping up anymore, just could not support very well that kinematics or that series of kinematics. So we looked at several packages. We needed something with better post processors, better tool path methodology, better strategies.

The Search Begins

We looked at the spectrum of all the CAM packages out there. We looked at NX, we looked at HyperMILL. At SolidCam. We looked at Edgecam. We looked at Autodesk, PowerMill, SolidCAM, SmartCAM. Esprit, Mastercam, GibbsCAM… there are a couple of other software companies that didn’t even call me back. End of the day, a lot of them took themselves out of the running as they were on a subscription basis that I can’t go on… if the software disappears or is not supported tomorrow, I can’t be without a programming system. So that marketing scheme just isn’t going to work for us.

NX vs Esprit

Our gear division uses Esprit across the street. But they pretty much primarily just use it for turning in our Mazak Mill turns that they were drilling some holes, but it generally was never anything that was really considered full-on four or five-axis machining. They’re just fantastic for mill turn and I look at it, and I kind of questioned — wait a second here. This doesn’t look any better than SurfCAM — looks like a lot of the same. It didn’t do a lot of volumetric checks, it did simpler 5-axis tool paths but NX was much better.

Siemens NX vs SURFCAM

After two years of trying to write post processors for that machine that we were not getting to the finish line… SURFCAM just wasn’t keeping up anymore, just could not support very well that kinematics or that series of kinematics.

— Charles Stangland, Programming Manager at Machinists Inc.

NX vs Edgecam

We went through a full training on Edgecam, but it was kind of all over the place. It was haphazard and I had to eliminate that one.

NX vs Autodesk

I looked at the Autodesk products. However, they were on a subscription basis that I can’t go on, which ruled them out as an option.

NX vs SolidCAM

We looked at SolidCAM. It did fairly simple work really well, but 3-axis work fantastic. Just fantastic strategies, fantastic tool path, but when they got into four or five-axis Mill-Turn, it seemed to kind of struggle and did not seem like it was going to be a good fit for our shop.

NX vs PowerMill

Taylor: Anything more that you can say about some of our competitors that you either liked or didn’t like? And why we were different? I’m specifically thinking of HyperMill and PowerMill.

Charles: So obviously PowerMill was one of those subscription-based softwares — fantastic-looking software. The programmers were really excited about it. But when we found out it was subscription-based, it totally poisoned the whole idea — we just walked away from it. We just couldn’t go there. You know, we can’t put a bunch of effort into writing post-processors and a bunch of effort into learning how to how to run a tool, and then suddenly have the tool gone, maybe a year from now.

NX vs HyperMill

We looked at HyperMill — HyperMill is a real high-end Five-Axis software. HyperMill does absolutely fantastic in high-end machines, but they don’t do simple 3-axis stuff — it’s not as well supported. When you try and use it for simple, 3-axis work, it writes the tool path, but generally, it’s with so much code that you completely choked some of the older controllers to where they cannot produce parts. You have to drip through them. You have to break programs down into smaller chunks… it did not seem like a good fit, even though it could support those high-end machines that we have.

NX on the other hand, supported everything really well from top to bottom. We could get Mill-Turn support, we could get support on our 5-axis and very complex, very intricate code. But then again, for the older 3-axis boring Mills, we could get more rudimentary code that worked fairly well on those machines. So at the end of the day, that’s kind of what drove our decision towards NX.

And you know, we’re also looking for a large user base. We’re looking for a pool of programmers that we could pull from, and we were looking for software that was also still being developed and still moving forward too.

The one that fit all the packages well and checked all the boxes was Siemens NX.

– Charles Stangland, Machinists Inc. Programming Manager

The Evaluation Process

Taylor: Okay, so the initial process… you guys reached out to us and we came on-site and did several demonstrations for you guys.

Charles: Actually, I reached out to Siemens as I didn’t know who to contact; then Siemens had you reach out to me from there. I contacted Siemens and said, I need a retailer in my area, and who do I talk to? The next thing I know I’m getting a call from Applied CAx.

Taylor: What was that process like for you… from someone that’s looking at buying software and trying to evaluate… you reach out to Siemens and then you get a call from me.

Charles: Yes — from there you did an online demonstration, which was very good. I sent you some sample parts… to all our different perspective software packages and see how everybody could approach them. What kind of code it was going to produce, and what level of complexity to program those parts. That’s where we got down to where NX, HyperMILL, and Solidcam seem to be the three contenders among the rest that really seemed like it was going to stand out.

Taylor: So what made you choose Applied CAx as a Siemens partner? Was the fact that we had a machine shop and we actually had programmers or were using the tools day in and day out?

Charles: When C-A-X reached out again, you guys kind of describe yourself: “Okay, we run our own machine shop, and so we know Machining, we use this tool in our shop. But we also do the support, we do the sales side of it..” It was that really that support, knowing that we have somebody that actually uses the software.

Taylor: that’s great. So what would you say is the best part about working with Applied CAx, and what would you tell somebody else that’s looking to look at NX or Applied?

Charles: Yeah, so C-A-X, whenever we call, whenever we send an email for support, it’s pretty much — if we don’t hear an answer right away, you guys are working on it and working on an answer. And if need be, you guys can reach out, further up to Siemens. They get some of our more advanced questions answered. You guys got very good people in each of the categories being post, being documents, and background processes and tool paths.

Taylor: You said earlier that whenever you come to us with a problem or a challenge it seems like we take that as a personal mission to go on kind of resolution for you.

Charles: That’s what it comes out to — C-A-X takes on looking for solutions to our problems as we’re looking for support as a personal mission.

Taylor: Well, it’s been awesome to see. I’m so glad that you guys are a client of ours and we’ve had an opportunity to work together and help you guys make the transition. It’s definitely been a fun project for us. So I know the team really likes working with Machinists Inc…

Charles: Oh man, sometimes I kind of wonder if you guys like us because I know how much we call for support. (Laugh out loud)

Taylor: We talked about the 4-axis part that you sent us early on when you were still evaluating NX CAM, and that one 4 axis part you mentioned and SURFCAM was taking you 40 or 50 hours to figure out how to program it. You invested a lot of time there, and within an hour and a half, we had a good quality tool path back to you and him quickly. Can you kind of go into that?

Charles: Yeah, so we had a 4-axis part that wasn’t a super high dollar part, and it was a very challenging part for SURFCAM to try and process 4-axis, because it needed a lead-lag angle for running a CAM profile surface. And we were really struggling, trying to get SURFCAM to produce the tool path that we needed and wanted, so I threw it over to C-A-X to say, “Okay, what can you do on a part like this?”

This is not hard. It’s not rocket science. So it should be fairly easy for most CAM packages to do, but why are we struggling so hard? Within an hour and a half, I had a working tool path back from Applied showing exactly how you guys would process that part. And yes, it was putting the lead angle, the lag angles on the surface just like we needed.

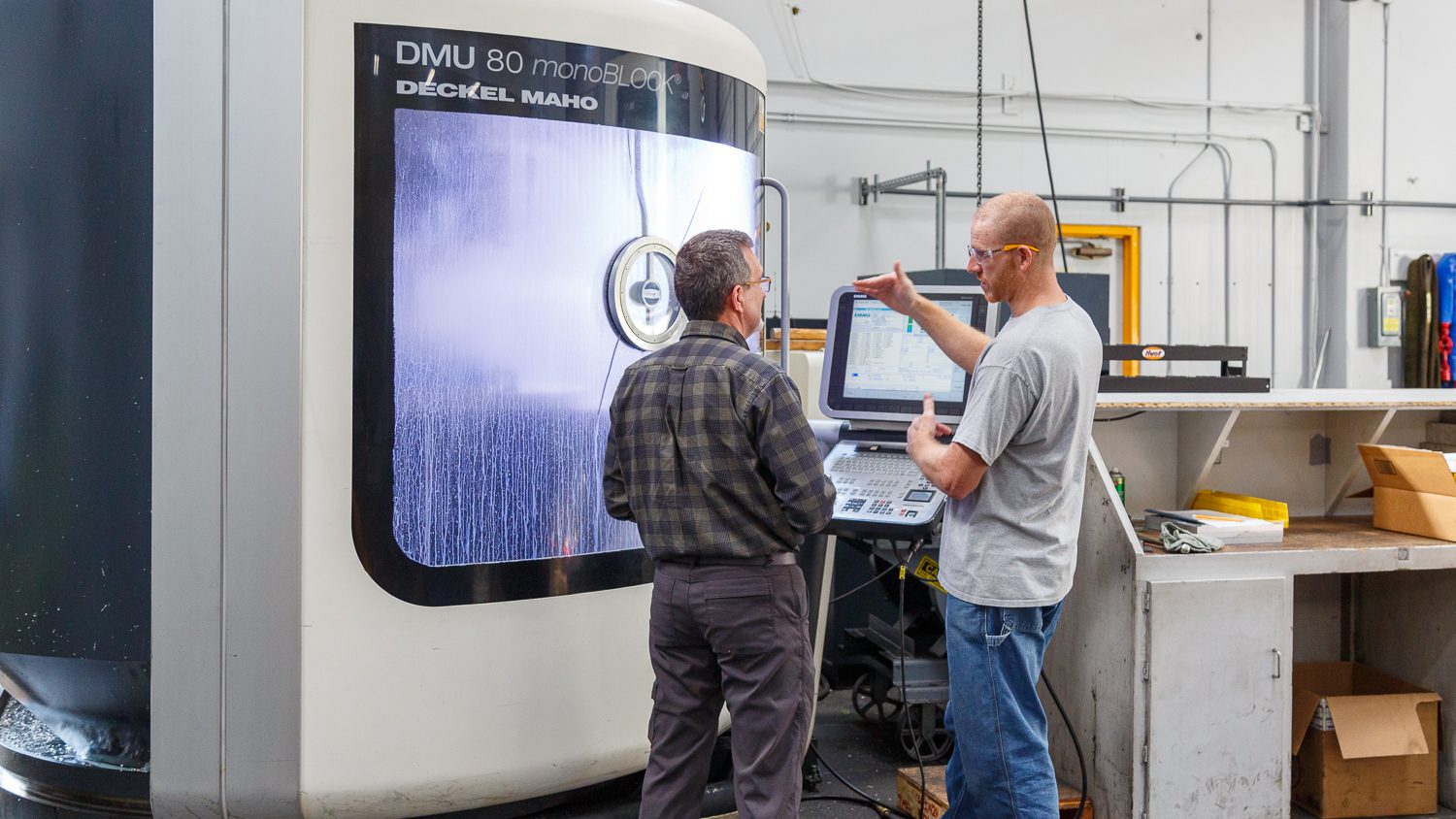

Taylor: Okay, one last thing I can think of Charles- can you talk us through the CAM training a little bit? I call we came on-site and did a four-day training, with a fifth day of CAD for CAM, four days of actual CAD cam training for Milling. back and did a couple of separate days just to focus on ways in turning. What was that like and what would you say the quality of our training is?

Charles: It was absolutely fantastic. Almost all of our questions were completely answered. I mean there were a few that we ask that Yes, your experts had to go back and actually ask the questions to someone further up. But the quality of training was very good at showed us the design intent of the file, how you set it up, at what you’re looking for, How your need to Process the part in order to be successful.. and yeah, it just was fantastic.

Taylor: Anything else that you can think of from a Machinist Inc standpoint that we can help do for you guys?

Charles: I just think continued good support that you guys have provided— That’s what we’re looking for and C-A-X going forward every year cause we’re on maintenance and needing support. I mean, we will always need support. It’s a very daunting programming system, but there’s a lot of capability there. And we definitely see it as the path forward in the future.

Interested in trying a free trial of NX CAM? Click here.